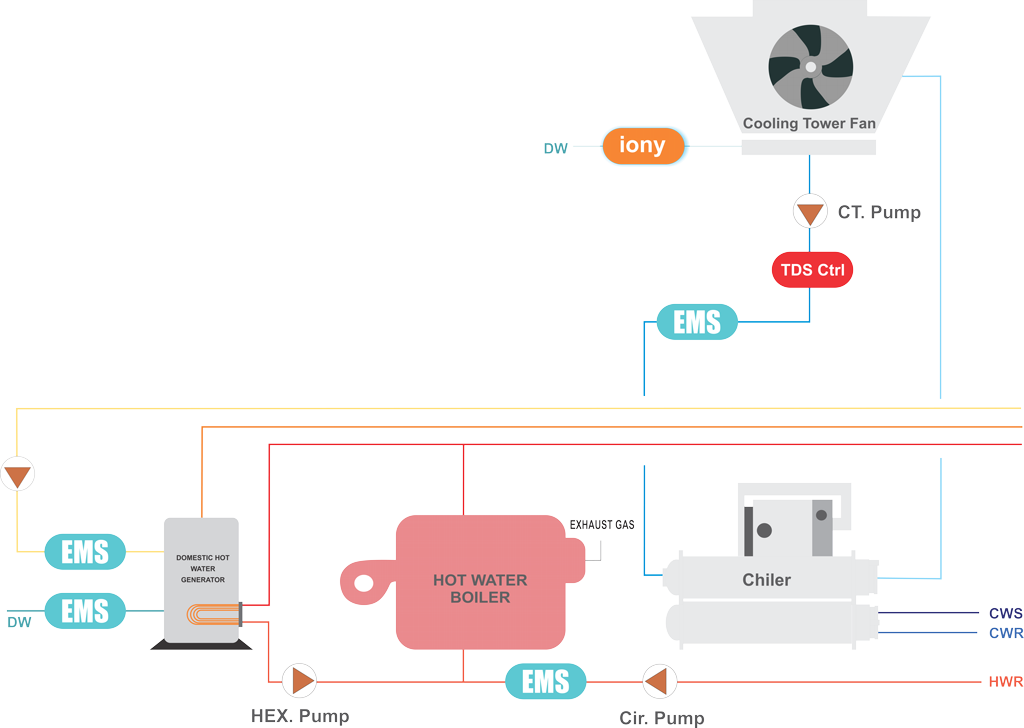

Hot Water Generators

EMS is installed in the cold water inlet to prevent limescale deposition on copper coils or surfaces.

If there is an inlet for domestic hot water return, another EMS is recommended there to help the main EMS

For this kind of equipment, EMS improves efficiency and declines the need for periodically acid-wash dramatically. The Ca++ and HCO3- ions turn into neutral crystals and exit the system through the faucet instead of depositing on hot surfaces and forming limescale

Chiller and cooling tower cycle

EMS is installed after the pump at the inlet of the condenser (absorber in absorption chiller) and removes limescale in the chiller (condenser/ absorber) and the cooling tower (especially nozzles and packings).

It neutralizes Ca++ and HCO3- ions and turns them into suspended crystals that can settle down at the cooling tower basin or be filtered from the circulating water.

Hot Water Generators

EMS is installed in the cold water inlet to prevent limescale deposition on copper coils or surfaces.

If there is an inlet for domestic hot water return, another EMS is recommended there to help the main EMS

For this kind of equipment, EMS improves efficiency and declines the need for periodically acid-wash dramatically. The Ca++ and HCO3- ions turn into neutral crystals and exit the system through the faucet instead of depositing on hot surfaces and forming limescale

EMS in hot-water boilers

EMS can be installed anywhere in the cycle, but the best place is the inlet of the boiler, to neutralize Ca++ and HCO3- ions and prevent the limescale deposit formation in the boiler and pipes